Archives: Blogs

Displays Blogs and their ratings

However, the regulatory landscape is evolving. In the United States, for example, there’s a growing push for stricter regulations on the use and disposal of PFAS across various industries, including electronics. Similarly, the European Union is considering a “One Substance, One Assessment” approach to streamline and enhance its management of chemicals like PFAS.

Trends toward tighter PFAS regulation are also being observed in other regions of the world. Wherever the mandate exists for increased transparency around PFAS usage and improved disposal practices, it will lead to safer working environments, more limited human exposure to the chemicals and reduced environmental pollution.

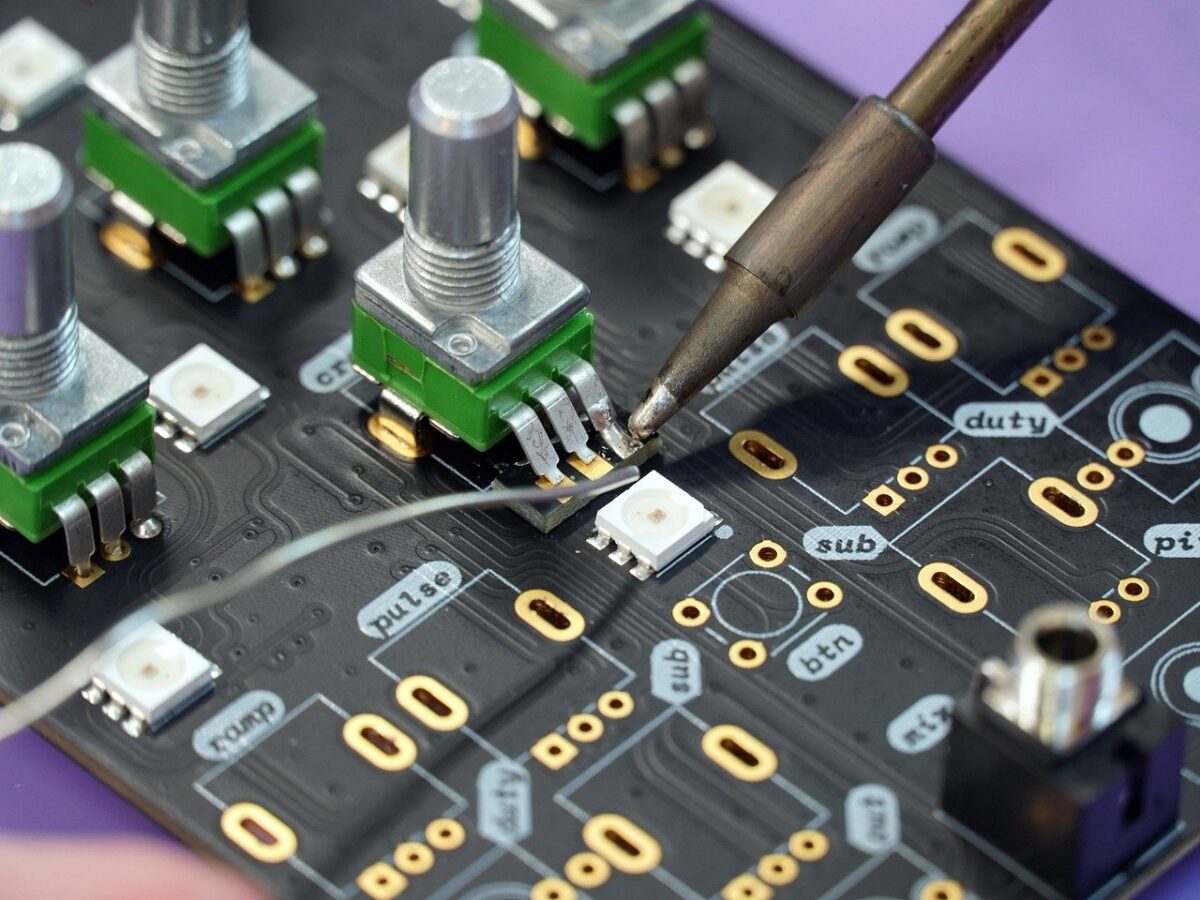

Overall, PFAS tonnage in electronics amounts to anywhere between 1,000 and 10,000 tonnes annually, with 5-25% of these chemicals being released from products during the manufacturing and use phases. That’s a significant quantity to consider, knowing that there are estimates that the volume of electronics sold will increase over the coming years, not decrease. To counter this trend, let’s now review what we know about the current and upcoming regulations.

Europe

As part of the European Union’s sustainability strategy, through the European Chemicals Agency’s (ECHA) REACH framework, the EU has already restricted perfluorinated carboxylic acids (C9-14 PFCAs) along with PFOS and PFOA. These restrictions remain in place. Additionally, the EU has made a new PFAS regulatory proposal, submitted in January 2023 by five EU member states (Denmark, Germany, the Netherlands, Norway, and Sweden).

On March 22, 2023, the EU initiated a 6-month consultation period open to feedback from stakeholders while the PFAS committee evaluates this new restriction proposal before it is submitted to the European Commission in September 2023. This new regulation, when passed, will make the EU one of the strictest areas of the world concerning PFAS regulatory compliance. Already, the EU considers LC-PFCAs, PFHxS, PFOA, and PFOS as persistent organic pollutants (POP). But the EU is still deciding about restrictions related to PFHxS and PFHxA. Any foreign company importing products with these chemicals into the EU should carefully check the status of these restrictions or face potential legal repercussions, financial penalties, or even loss of goods.

North America

In the United States, the Environmental Protection Agency (EPA) has proposed the classification of PFOA, PFOS, and five other PFAS substances as “hazardous” under the Superfund law (CERCLA). Such a classification makes electronics manufacturers liable for post-release cleanup of these substances, significantly affecting design and manufacturing practices. The current administration has voiced a commitment to addressing PFAS effects in the environment. As such, the EPA has developed, as a key component of the administration’s response, a comprehensive document, called the PFAS Strategic Roadmap, and a new interactive website: PFAS Analytic Tools.

But that was just at the federal level. More than a half-dozen states already have or are enacting PFAS regulations in 2023, with Maine having banned the use of PFAS in any product, including a sweeping requirement for all companies to report or make public the amount and purpose of PFAS use (see LD 1503). On July 1, a California law, AB 652, took effect, banning the sale and distribution of new children’s products containing PFAS, including certain electronics. Companies are now required to use the least toxic alternative, which may vary according to product, but the law excludes electronic products and internal product components that will not have contact with the skin or mouth. Other upcoming California laws can be found here.

Whether the reforms from additional states will immediately affect the electronics industry or begin to influence PFAS regulations concerning the electronics industry is still unclear. However, we will list them anyway, because they give you a sense of the momentum behind US state PFAS regulation.

- Hawaii’s new PFAS law, HB 1644, bans the manufacture, distribution and sale of some food packaging containing PFAS, include wrapping, liners, plates, food boats and PFAS boxes. The law also prohibits firefighting foams that contain PFAS. Such foams are used to extinguish gasoline, oil and jet fuel.

- Rhode Island’s SB 2298 law requires public water utilities to regularly monitor the use of six PFAS chemicals, particularly in drinking water. If PFAS levels exceed the established limit, entities are required to provide potable water to residents through other means until the levels reach an acceptable limit.

- Vermont’s S.20 law bans intentionally added PFAS from food packaging, residential rugs, carpets, and ski wax. Additional information can be found in the Vermont PFAS Roadmap.

- Minnesota’s state agencies have collaborated to address PFAS contamination. Their approach, named the “PFAS Blueprint,” strategizes short to long-term methods of preventing, managing and cleaning up PFAS, with a focus on research, health guidelines and water/food protection. Additionally, a stringent PFAS monitoring plan is in place, particularly focusing on waste management facilities, while landfills using spray irrigation are being closely regulated to maintain PFAS levels below health-based values.

These regulations may already affect electronics, depending on your company’s PFAS-related activities, so it’s best to check thoroughly through the current legislation in these states (and any others you may do business in). It is widely expected other states will follow suit, and that this regulatory trend will expand as the word gets out about PFAS-related health and environmental threats.

Concurrently, Canada’s PFAS guidelines may influence broader environmental policies, calling for alterations in electronic component sourcing and manufacturing. For a breakdown of PFAS regulations in Canadian provinces, take a look at this article.Australia, Asia, South America, and Africa

- Australia’s PFAS regulation and the PFAS National Environmental Management Plan (NEMP), focusing on the phase-out of long-chain non-polymer PFASs and restrictions in firefighting foam, are starting to pose challenges to the electronics industry. See the Australian government’s PFAS information portal for details. Also, take a look at the forum for giving feedback at the National Environmental Management Plan on PFAS.

- In Asia, the regulatory landscape varies across countries. In 2021, China announced its plan for managing new chemical pollutants. You may also want to check out China’s chemical substance controls. Japan has implemented stringent PFAS regulations, categorizing PFOA and PFOS as a Class I Specified Chemical Substance, and South Korea is working toward greater regulation under the Persistent Organic Pollutions Control Act after extensive studies. Taiwanese companies account for roughly 50% of the world’s semiconductor market, and the Toxic Chemical and Substance Bureau of Taiwan has banned or restricted PFAS chemicals, having classified them at various levels of toxicity.

- Although Brazil has not updated its potability standards or provided new guiding values for soil and groundwater to include PFAS, CETESB aims to advance the country’s regulatory framework for emerging contaminants and implement PFAS detection methods and monitoring in the State of São Paulo by 2023 (see LINK). The Biden and Lula administrations are working jointly on various PFAS regulatory initiatives.

- As of yet, there has only been preliminary studies in certain African countries, in addition to countries, like South Africa, phasing out of products containing PFOS and PFOA. However, a larger issue for the electronics industry and African countries is on the post-consumer electronics waste side of the toxic chemical equation. For a comprehensive study on POP-related waste issues in African countries, including some information on electronics waste, see this study.

- Assessment: First assess your company’s use of PFAS both in the manufacturing process and in the materials used to produce your products. This requires accessing all data related to the processes and the materials used.

- Substitution: Look for safer alternative materials to replace the use of PFAS in the production process. Several alternatives, such as hydrocarbon-based materials, have already been developed for many applications of PFAS. It’s important that alternatives are fully vetted to ensure they don’t pose similar or other health and environmental concerns.

- Containment: Implement improved containment methods in the manufacturing processes to reduce potential PFAS releases. This can include enhanced engineering controls and closed-loop systems.

- Staff Training: Ensure that all staff are well trained in the handling and disposal of materials containing PFAS. A well-informed workforce can significantly decrease the likelihood of accidental releases.

- Protective Equipment: Provide adequate personal protective equipment (PPE) for employees who work directly with PFAS-containing materials to reduce their direct exposure.

- Waste Management: Implement rigorous waste management practices, including proper disposal of PFAS-containing waste. If possible, explore opportunities for waste treatment technologies that can break down PFAS, such as plasma treatment, photolysis, Advanced Oxidation Processes (AOPs), biodegradation and electrochemical treatments.

- Supply Chain Engagement: Engage with suppliers to encourage them to reduce or eliminate their use of PFAS in products supplied for manufacturing processes. This can involve adopting procurement policies that favour suppliers who minimize or eliminate PFAS in their products and the use of supply chain mapping software, such as CleanChain.

- Monitoring & Reporting: Regularly monitor PFAS use, emissions and worker exposure levels. Transparent reporting of these levels not only fosters trust with employees and the community but can also highlight areas where improvements can be made, hopefully leading to the total elimination of PFAS from your supply chain and processes.

- Innovation & Research: Invest in research and development of non-PFAS materials for use in your products. Encouraging innovation in this area can lead to long-term solutions that are safer for both the environment and human health.

- Policy Advocacy: Support policies and regulations that aim to reduce PFAS use and exposure. Companies can play a significant role in shaping industry standards and regulations.

- Partnerships: Reach out to organizations and governmental agencies to gain access to information about PFAS legislation and to learn about the resources available to businesses to tackle the PFAS challenge in electronics.

Understanding PFAS in Sparkling Water

Recent reports have raised concerns about the presence of Per- and polyfluoroalkyl substances (PFAS) in some brands of sparkling water. PFAS are a group of synthetic chemicals that have been linked to a variety of adverse health effects and have been used in industries around the globe since the 1940s. Due to their strong bonds and resistance to heat, water and oil, these chemicals have been used in products ranging from non-stick cookware to fire-fighting foams. PFAS are known as “forever chemicals,” because they do not break down easily in the environment or the human body, meaning they can accumulate in you over time. They can enter the human body through various routes, such as consuming contaminated food or water (including store-bought and tap water), inhaling air containing these chemicals or through skin contact. Studies have indicated that exposure to these substances may have several potential health impacts. These include:

- Developmental issues: High prenatal (before birth) or postnatal (after birth) exposure to some PFAS can result in low birth weight, smaller head circumference and developmental delays in infancy and childhood.

- Immune system effects: Some studies have shown that PFAS exposure can impact the immune system, resulting in decreased vaccine response and potentially increasing the risk of autoimmune diseases.

- Cholesterol levels: Certain PFAS may increase levels of cholesterol in the blood, a risk factor for heart disease, stroke and other ailments.

- Cancer risks: Some studies have found associations between PFAS exposure and increased risk of certain cancers, particularly kidney and testicular cancers.

- Hormonal disruptions: PFAS can interfere with natural hormones in your body, which can impact a range of functions including metabolism and reproductive health.

- Liver function: Exposure to some PFAS can affect liver function, potentially leading to changes in liver enzymes and increased risk of liver damage.

It’s important to note that the specific health effects can vary depending on the type of PFAS, the level and duration of exposure and individual health factors. But given this concern, it’s crucial to understand how to avoid PFAS in sparkling water to maintain a healthy lifestyle. Here are some tips you can follow:

Check Labels & Brand Websites

Brands that are committed to quality and health will often display relevant information about their products on their packaging or websites. Look for statements about PFAS testing or filtration. Brands that test their water for PFAS and have an effective filtration system in place are likely safer options.

Research Brands

Even if brands don’t provide information about PFAS testing on their packaging or website, you can reach out to them directly or conduct some independent research online. Many consumer advocacy groups, scientific researchers and public health organizations conduct independent testing of consumer products for various contaminants, including PFAS. They typically publish these results online, so they can be a good source of information. Here are some links:

- Environmental Working Group (EWG), a non-profit, non-partisan organization dedicated to protecting human health and the environment. They conduct independent research and provide resources to help consumers make informed decisions. They have a comprehensive database about PFAS contamination in the United States.

- Consumer Reports is a trusted consumer advocacy organization that conducts rigorous research and testing on a wide range of products. They have tested for PFAS in a variety of consumer products, including water.

- Centers for Disease Control and Prevention (CDC)—their National Center for Environmental Health conducts research on the health effects of PFAS and monitors exposure in the U.S. population.

- The Food and Drug Administration (FDA) conducts testing for PFAS and other contaminants in food and beverages, including bottled water.

- National Institute of Environmental Health Sciences (NIEHS), which is part of the National Institutes of Health, conducts and funds research on the health effects of PFAS.

- Silent Spring Institute is a scientific research organization that focuses on environmental chemicals and women’s health. They have conducted research on PFAS in drinking water and other products.

Avoid Certain Packaging

While the sparkling water itself may be free of PFAS, the packaging might not be. PFAS can be found in food packaging, including certain types of bottles and cans, due to their water and grease-resistant properties. Look for brands that use PFAS-free packaging. If you’re unsure, you can contact the company or look for independent testing of packaging materials.

Opt for Glass Bottles

Glass bottles are generally a safer bet when it comes to PFAS contamination. They don’t contain PFAS or other potentially harmful chemicals found in some plastic and metal packaging. In addition to being safer, they’re also more environmentally friendly—as long as you recycle them and don’t just throw them away (and confirm that your community recycling systems actually reuse or recycle the particular types of bottles you buy – always check to be sure).

Consider Home Carbonation Systems

If you’re a frequent consumer of sparkling water, investing in a home carbonation system could be a good choice. This allows you to control the quality of the water you’re using. Just ensure that the water you’re carbonating is filtered and free of PFAS by looking at relevant studies.

Use Certified Water Filters

Whether you’re using a home carbonation system or just want to ensure your drinking water is free of PFAS, a water filter certified to remove PFAS can be a good investment. Remember to regularly replace filters as per the manufacturer’s instructions to ensure they continue to work effectively.

Advocate for Better Regulations

Beyond testing yourself for PFAS exposure, on a broader scale, one of the most effective ways to avoid PFAS in sparkling water is to advocate for stronger regulations on these chemicals. Support organizations that are fighting for stricter PFAS regulations and vote for policymakers who prioritize clean water and public health.

While the presence of PFAS in sparkling water can be concerning, being proactive and educated can help mitigate risks. By following these steps, you can enjoy your sparkling water with less worry about potentially harmful substances. After all, knowledge is power when it comes to your health. So, keep informed, choose wisely and drink healthily!

If you work for a manufacturing company seeking to remove PFAS from your products or operations, check out our PFAS PAGE for more in-depth information.